An abstraction layer is a thinking tool that enables us to temporarily ignore some parts of a problem. Thinking in terms of abstraction layers allows an engineer or scientist or any problem solver to focus on a specific aspect of a problem, as the wider environment and associated complexity is temporarily ignored. The language of abstraction layers is common in software engineering and computer science, where many libraries, frameworks and protocols sit atop one another [1].

One example of an abstraction is buying our food from the supermarket. All of the underlying physical reality and complexity of growing food, keeping it fresh and transporting it from the farm to market is more-or-less abstracted away from the consumer. However at some point, these abstractions begin to break down or to “leak”, in fact it has been posited that all abstractions end up leaking to some degree [2]. The supermarket abstraction begins to leak, for example, when a global pandemic hits food supply chains and consumers find the supermarket shelves empty. When this happens the consumer is forced to consider; where does all this food come from anyway, and should I grow my own food? The leak in the abstraction has laid reality bare.

The science of sustainability often involves attempts to reveal the physical reality that has been obscured by abstraction. Here the abstraction is created by our industrialised and consumerist society, whereby the consumer is disconnected from the manufacture of goods and services, and the entailing environmental degradation [3]. This disconnection comes about due to the complex and interconnected nature of global production and trade, as well as the pattern of shifting or ‘externalising’ pollution to other countries or regions – where the impacts are out of sight [4].

There are modelling techniques available that can unravel the complex web of inputs and impacts along global supply chains [5]. These techniques attempt to account for all the processes that contribute to the goods and services we consume. This allows environmental impacts to be traced to specific consumption activities, despite the impacts and consumption events being separated in time and space.

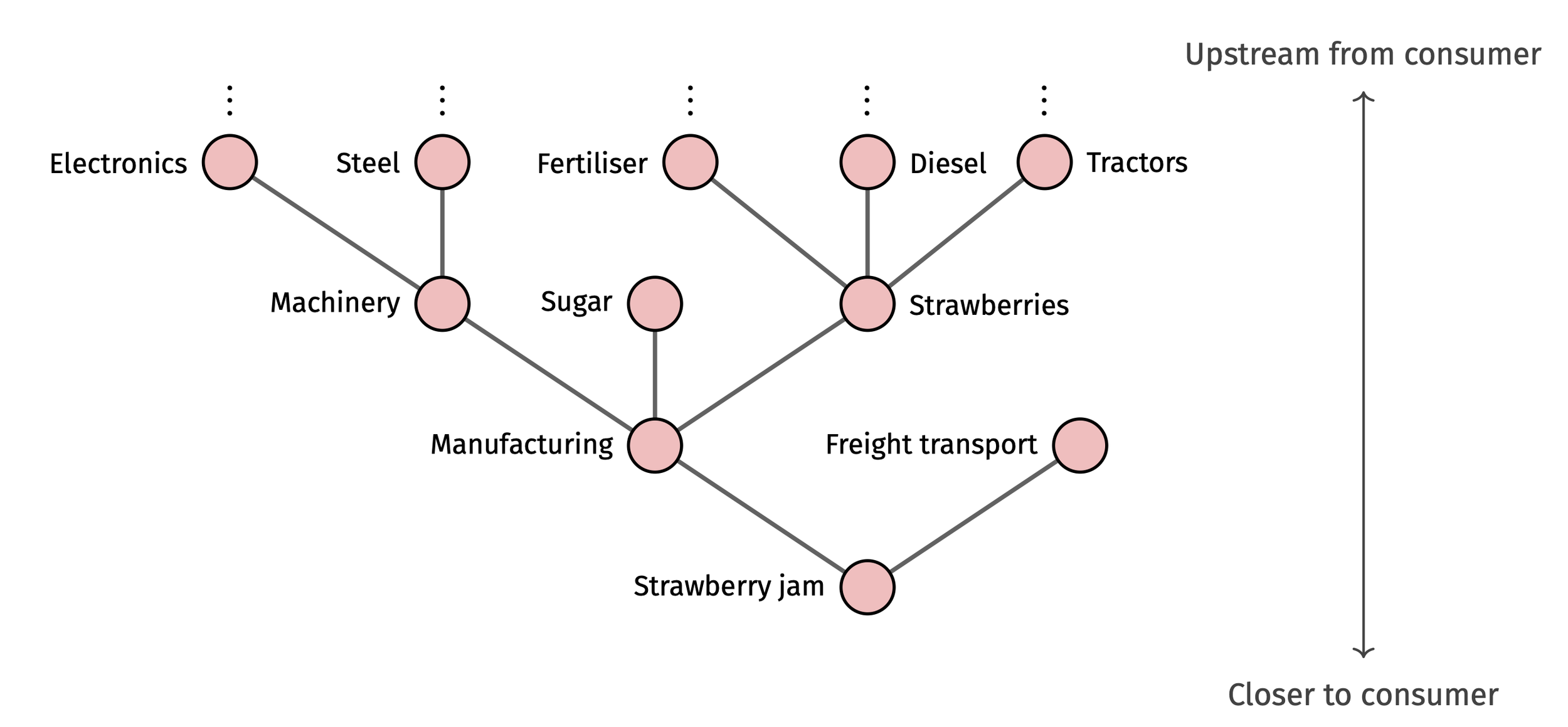

Using these models allows us to peel-back the production layers and traverse the supply chain, hopefully revealing more of the underlying physical reality. This is demonstrated in the fictitious strawberry jam supply chain shown above. Each step away from the consumer upstream reveals another production layer and set of inputs. These techniques rely on large environmental economic models which knit together the world’s production, trade, consumption and environmental data [6]. The models give us insights into the far fringes of our supply chains, however represent reality only in aggregate – individual supply chains may deviate from those in the model.

Other tools exist to follow goods along supply chains in real-time, and have applications in the freight transport, fishing, cold-chain and food industries [7]. These tools come under the broad heading of supply-chain transparency and chain-of-custody techniques [8]. These techniques differ from the supply chain models in that they usually track an individual product, rather than attempting to account for the innumerable contributing components to a complex product.

These tools are all attempts to reconstruct the past of a product and provide consumers better information about the real costs and environmental impacts of their purchases. However, perhaps this strategy has limits: we may not be able to unravel the full impacts of our actions in the world and therefore should tread as lightly as possible.

[1] See for example, https://en.wikipedia.org/wiki/Fundamental_theorem_of_software_engineering

[2] https://www.joelonsoftware.com/2002/11/11/the-law-of-leaky-abstractions/

[3] Erb at al., 2009, Embodied HANPP: Mapping the spatial disconnect between global biomass production and consumption, Ecological Economics

[4] Peters, G et al., 2011, Growth in emission transfers via international trade from 1990 to 2008, PNAS

[5] Techniques such as Input-output Analysis and Life Cycle Assessment.

[6] These databases include EXIOBASE, GLORIA, EORA and others.

[7] See for example: https://www.enkibox.com.au/, https://opensc.org/.

[8] https://hbr.org/2019/08/what-supply-chain-transparency-really-means

This post first appeared on the Shrunk Labs blog: https://shrunk.ai/blog/f/supply-chain-abstraction-and-reality